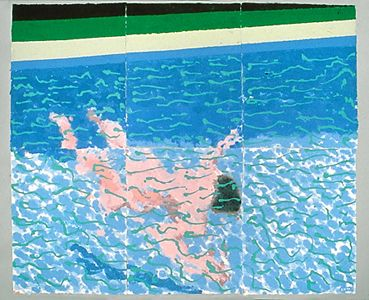

David Hockney: From the 'Paper Pool' series

Nearly all drawing practices use paper in one form or another and the choice of what type to use has always been a central issue for the drawer. If you are also a printmaker you will be also be involved in having to make decisions as to what sorts of papers to use, as paper surfaces directly impact on the final image. We now of course have to also consider sustainability. The positive thing is that when produced from wood sourced from sustainably managed forests, paper is a renewable material. Healthy forests act as carbon sinks, binding CO2 from the atmosphere and helping to mitigate climate change. With responsible sourcing and sustainable manufacturing processes, paper is a material that could become part of a future circular economy, whereby there is no waste because of the sensitive handling of a mixed economy of both trees and related guild* planting, which together would support sustainable forest management.

*Starting with a large tree, you might encourage understory trees, nitrogen-fixers, bug repelling plants, and various forms of ground cover. A Guild is in effect a plant community that is self sustaining.

Making papers specifically for drawing and painting is a specific area of paper production and it has its own eco-climate. Different art papers have different effects on the environment due to their varying production processes. Paper production is also linked to different cultural traditions, Japanese papers having a very different aesthetic and manufacturing ethos to European paper production, which is again very different to Indian traditions.

Traditional paper making is mainly driven by processes associated with cotton or wood based materials.

Cotton Paper

Cotton plants require vast amounts of water, and in some places around the world, have been known to exhaust local water access. However the fibres used in cotton paper production are usually a by-product of the textile industry and the clothing it is made from would most likely otherwise go to landfill. Handmade cotton rag papers are made from what is in the trade called post consumer fibres, i.e. items such as old t-shirts. They have the potential to achieve the lowest carbon footprint during production. For instance, pulp can be dried slowly in the sun, and the water used to turn the rags into pulp can be run off to irrigate neighbouring fields. Because cotton paper pulp is naturally pH neutral the water does not have a negative impact upon the surrounding environment.

Wood Paper

It does seem that the majority of trees that are used in Western Europe, the US and Canada to make paper are sustainably farmed. However this is not the case everywhere. In England fine art paper mills mainly use virgin pulp imported from Western Europe because the quality of the fibres means that the resulting paper can withstand heavy treatment, such as being scrubbed or laden with watercolour washes. Trees for papermaking are usually grown specifically for that purpose, to ensure consistency, and countries such as Finland, Sweden, Canada and the US all at the moment grow trees for papermaking faster than they are felling them. This is obviously a good thing, but there are issues related to mono species economies. Multispecies plantations have a higher yield, quicker growth rates, and a better overall economic return than monocultures but this fact doesn't seem to have been understood by the sector as a whole and like so many areas of mass agricultural production too many companies rely on single species growing policies, which is unsustainable in the long term.

Energy

The principal source of energy for paper mills is natural gas and electricity, although coal, oil, biomass and solar energy are sometimes also used. The production of most fine art paper is not as energy efficient as the production of other papers for general use. This is because the mould made processes are much slower. Fine art paper mills favour this slower process because it allows heavier weights of paper to be made, and it also successfully ensures that the paper made is robust and has a surface suited to artwork. There are only three mills making fine art paper, out of nearly 70 mills in total in the UK, so while it may not be a very energy efficient industry, the net energy usage accounted for by fine art paper manufacture is comparatively very low.

In Japan making traditional art papers is a human centred tradition and it uses far less machinery than European methods, most of the equipment being hand made and operated using human labour.

In India there are other traditions the best of which use run-off from the papermaking processes as a fertiliser, so that in certain instances the environmental impact can be positive.

Traditional Nepalese paper moulds use a wooden frame with a thin cotton cloth stretched over its surface. The paper is dried on the frame which is propped up and angled towards the sun. This is one of the oldest ways of making paper, unchanged for over 1000 years and it is also one of the most environmentally safe.

Bleaching

Bleaching is used in the whitening process of paper, but this has a significant environmental impact, particularly for the aquatic environment, due to the harmful emissions that are released when using chlorine based bleaches. For this reason, look for papers that are elemental chlorine free (ECF) as a minimum standard. The three main classifications to look out for are totally chlorine free (TCF), elemental chlorine free (ECF) and process chlorine free (PCF). You can of course choose to not use white paper, a tonal standard that itself has a history as well as associations with Modernism and an idea of purity. The association of paper with purity and whiteness is a 19th century one that has somehow stuck and is very much a product of the advance of the medico-chemical industries and how they have for instance marketed ideas about the need for sterilisation in order to avoid hidden germs and the chemical advances behind optical brightening agents, things for which there is no real need, except to advance the myth of cleanliness being next to godliness, as the manufacturers of Pear's soap would have it.

The artists Barbara Landes and Paul Sullivan use a variety of paper making techniques

to produce their own handmade paper, which is then used to fabricate sculpture.

Making papers specifically for drawing and painting is a specific area of paper production and it has its own eco-climate. Different art papers have different effects on the environment due to their varying production processes. Paper production is also linked to different cultural traditions, Japanese papers having a very different aesthetic and manufacturing ethos to European paper production, which is again very different to Indian traditions.

Traditional paper making is mainly driven by processes associated with cotton or wood based materials.

Cotton Paper

Cotton plants require vast amounts of water, and in some places around the world, have been known to exhaust local water access. However the fibres used in cotton paper production are usually a by-product of the textile industry and the clothing it is made from would most likely otherwise go to landfill. Handmade cotton rag papers are made from what is in the trade called post consumer fibres, i.e. items such as old t-shirts. They have the potential to achieve the lowest carbon footprint during production. For instance, pulp can be dried slowly in the sun, and the water used to turn the rags into pulp can be run off to irrigate neighbouring fields. Because cotton paper pulp is naturally pH neutral the water does not have a negative impact upon the surrounding environment.

Wood Paper

It does seem that the majority of trees that are used in Western Europe, the US and Canada to make paper are sustainably farmed. However this is not the case everywhere. In England fine art paper mills mainly use virgin pulp imported from Western Europe because the quality of the fibres means that the resulting paper can withstand heavy treatment, such as being scrubbed or laden with watercolour washes. Trees for papermaking are usually grown specifically for that purpose, to ensure consistency, and countries such as Finland, Sweden, Canada and the US all at the moment grow trees for papermaking faster than they are felling them. This is obviously a good thing, but there are issues related to mono species economies. Multispecies plantations have a higher yield, quicker growth rates, and a better overall economic return than monocultures but this fact doesn't seem to have been understood by the sector as a whole and like so many areas of mass agricultural production too many companies rely on single species growing policies, which is unsustainable in the long term.

Recycled Paper

The existing paper manufacturers that specialise in art papers believe that it is not possible to use entirely recycled pulp for fine art use, because the re-pulping process necessary when recycling shortens the fibres, reducing the strength of the end product. Additionally, when making recycled paper, it is very hard to know what sort of chemicals might be present in any pulp produced from used papers. Paper that has had a previous life serving non-fine art purposes is likely to contain lignins or bleaches which will prevent the resulting paper from being archival. Therefore when recycled fibres are used to make drawing paper, some virgin pulp has to be added to compensate for the fibres that are no longer usable, as this minimises the percentage of impurities. Recycled paper also requires additional processes such as de-inking, degreasing and the removal of additives. Each of these comes with its own set of challenges, whether it’s the toxic sludge accumulated from de-inking or the undermining of the strength of the end product as a result of grease in the pulp. At the moment these problems have solutions that often require a prohibitive amount of energy and the use of even more toxic chemicals. Therefore recycled paper isn’t always the most environmentally friendly choice. I wanted to flag this up because several companies state that they produce recycled papers, but they rarely break down for their customers the issues involved.

Water

Water is a vital component in nearly all stages of papermaking. If water is to be returned to source it needs to be carefully filtered to remove any additives that may be harmful to local plant and river life. Wastewater treatment is categorised into primary, secondary, and tertiary treatments. Primary treatment uses sedimentation to remove suspended solids from wastewater, forming sludge. Secondary treatment removes organic matter using biological processes. Tertiary treatment removes any other contaminants required before discharge into the receiving environment. Those three standard steps are altered or augmented depending on the nature of the facility and its processes. In the UK, paper mills associated with the making of fine art papers need to be looked at on an individual basis in terms of their sustainable water use. Good examples are Two Rivers (Exmoor Water) and St Cuthberts (River Axe) both being situated by a source of fresh flowing, naturally filtered water. These mills return the water they use to the river, free from any papermaking additives, often purer than when it was first extracted from the source. The thriving population of freshwater trout in the Rive Axe are testament to the cleanliness of the water that is issued by the St Cuthberts mill.

The existing paper manufacturers that specialise in art papers believe that it is not possible to use entirely recycled pulp for fine art use, because the re-pulping process necessary when recycling shortens the fibres, reducing the strength of the end product. Additionally, when making recycled paper, it is very hard to know what sort of chemicals might be present in any pulp produced from used papers. Paper that has had a previous life serving non-fine art purposes is likely to contain lignins or bleaches which will prevent the resulting paper from being archival. Therefore when recycled fibres are used to make drawing paper, some virgin pulp has to be added to compensate for the fibres that are no longer usable, as this minimises the percentage of impurities. Recycled paper also requires additional processes such as de-inking, degreasing and the removal of additives. Each of these comes with its own set of challenges, whether it’s the toxic sludge accumulated from de-inking or the undermining of the strength of the end product as a result of grease in the pulp. At the moment these problems have solutions that often require a prohibitive amount of energy and the use of even more toxic chemicals. Therefore recycled paper isn’t always the most environmentally friendly choice. I wanted to flag this up because several companies state that they produce recycled papers, but they rarely break down for their customers the issues involved.

Water

Water is a vital component in nearly all stages of papermaking. If water is to be returned to source it needs to be carefully filtered to remove any additives that may be harmful to local plant and river life. Wastewater treatment is categorised into primary, secondary, and tertiary treatments. Primary treatment uses sedimentation to remove suspended solids from wastewater, forming sludge. Secondary treatment removes organic matter using biological processes. Tertiary treatment removes any other contaminants required before discharge into the receiving environment. Those three standard steps are altered or augmented depending on the nature of the facility and its processes. In the UK, paper mills associated with the making of fine art papers need to be looked at on an individual basis in terms of their sustainable water use. Good examples are Two Rivers (Exmoor Water) and St Cuthberts (River Axe) both being situated by a source of fresh flowing, naturally filtered water. These mills return the water they use to the river, free from any papermaking additives, often purer than when it was first extracted from the source. The thriving population of freshwater trout in the Rive Axe are testament to the cleanliness of the water that is issued by the St Cuthberts mill.

Energy

The principal source of energy for paper mills is natural gas and electricity, although coal, oil, biomass and solar energy are sometimes also used. The production of most fine art paper is not as energy efficient as the production of other papers for general use. This is because the mould made processes are much slower. Fine art paper mills favour this slower process because it allows heavier weights of paper to be made, and it also successfully ensures that the paper made is robust and has a surface suited to artwork. There are only three mills making fine art paper, out of nearly 70 mills in total in the UK, so while it may not be a very energy efficient industry, the net energy usage accounted for by fine art paper manufacture is comparatively very low.

In Japan making traditional art papers is a human centred tradition and it uses far less machinery than European methods, most of the equipment being hand made and operated using human labour.

In India there are other traditions the best of which use run-off from the papermaking processes as a fertiliser, so that in certain instances the environmental impact can be positive.

Traditional Nepalese paper moulds use a wooden frame with a thin cotton cloth stretched over its surface. The paper is dried on the frame which is propped up and angled towards the sun. This is one of the oldest ways of making paper, unchanged for over 1000 years and it is also one of the most environmentally safe.

Bleaching is used in the whitening process of paper, but this has a significant environmental impact, particularly for the aquatic environment, due to the harmful emissions that are released when using chlorine based bleaches. For this reason, look for papers that are elemental chlorine free (ECF) as a minimum standard. The three main classifications to look out for are totally chlorine free (TCF), elemental chlorine free (ECF) and process chlorine free (PCF). You can of course choose to not use white paper, a tonal standard that itself has a history as well as associations with Modernism and an idea of purity. The association of paper with purity and whiteness is a 19th century one that has somehow stuck and is very much a product of the advance of the medico-chemical industries and how they have for instance marketed ideas about the need for sterilisation in order to avoid hidden germs and the chemical advances behind optical brightening agents, things for which there is no real need, except to advance the myth of cleanliness being next to godliness, as the manufacturers of Pear's soap would have it.

If you want to look into the issues that surround the association of whiteness with purity in more depth read:

Berthold, D (2010) Tidy Whiteness: A Genealogy of Race, Purity, and Hygiene The Journal of Ethics and the Environment Vol. 15, No. 1 (Spring), pp. 1-26 (26 pages) Published By: Indiana University Press

and

The Myth of Race: The Troubling Persistence of an Unscientific Idea New York: Harvard University Press

The myth of whiteness in operation

The need for sustainability in this case overlaps with the need for racial justice.

It is no accident that climate action and reduced inequality are both seen as vital to the attainment of the United Nations' sustainable development goals

Perhaps if you are worried about the sustainability issues surrounding the making of paper you could investigate making your own paper and once you do that this opens out all sorts of paper possibilities both as a building material and as a surface to work upon. In some cases artists use paper to fuse both these aspects together, building out from sheets of paper using pulp and folding techniques, so that complex structures can be envisioned.

to produce their own handmade paper, which is then used to fabricate sculpture.

Barbara Landes and Paul Sullivan

There are vast amounts of paper and cardboard out there to be recycled, so before beginning to use yet another clean, white sheet, do at least think about whether or not you could re-use some of the papers you will I'm sure be able to find in your near vicinity. However if you conduct a little research you may well find that a local company has large amounts of off-cuts or ends of rolls that they would be happy to let you have.

See also:

Japanese papermaking (use the links at the end of this post to explore more paper issues)

Key statistics: The European Pulp and Paper industry

Key statistics: The European Pulp and Paper industry

Rendering skin colour

Pulp It A site dedicated to the advantages of using paper as a building material

Pulp It A site dedicated to the advantages of using paper as a building material

Insightful post on paper sustainability! Agarwal Machineries, a pulp moulding machine manufacturer, aligns with this eco-vision through innovative pulp-based packaging solutions. A must-read for green manufacturing professionals!

ReplyDelete